Consumer demands for digital technologies are straightforward: Shortening the distance from point A to point B.

Businesses have increased direct to consumer options and online offerings to engage consumers, without requiring them to leave the comfort of their couch or office.

But when a consumer needs to physically move from point A to point B, innovating the method isn't as simple. And arguably, consumers are less likely to want disruption when safety is a concern (the Boring Company's next-generation offerings are a long way from completion).

Ride sharing apps have taken over transportation, but no application has disrupted air travel. Neither has an app changed the way people use elevators.

United Technologies Corp. was "founded on defying the laws of physics and with that comes life-critical systems," said Vince Campisi, SVP and chief digital officer of UTC. To modernize, the company's "process oriented, safety first" mentality has to embrace more agility, speed and develop an appetite for risk taking.

Though not a household name, UTC touts leading businesses like Otis elevators, aircraft propulsion brand Pratt & Whitney, UTC Climate, Controls & Security and UTC Aerospace Systems.

Billions of people regularly interact with its products, including the approximately 2 billion who use its Otis elevators, escalators and moving walkways every day.

Customer demands have driven companies to adopt digital technologies, reshaping industries like retail and food to embrace e-commerce. More industrial companies, however, have had fewer drastic digital changes disrupting core business.

Instead, manufacturers are under increasing pressure from cheaper competitors, mostly from Asia, according to Paul Miller, senior analyst at Forrester, in an interview with CIO Dive. If all a company is doing is making a bolt or an elevator, cheaper options from overseas are readily available.

Digital business helps make those products and services "stickier," Miller said. Technologies like digital twins and digital thread will weave into products and ensure existing customers come back, bringing new customers with them.

Maintaining the hallmarks of UTC's business requires balance and driving innovation requires a recipe that respects critical processes throughout disruption.

UTC's reinvention places around 70% of energy on business efficiency and helping the company operate more effectively, Campisi said, in an interview with CIO Dive. The other 30% is oriented around moonshots and new business models the company can experiment with.

Intermixed throughout is rethinking the relationship with the customer, considering how data and analytics could play a role in creating value, Campisi said.

CIO vs. CDO

When Campisi joined UTC two years ago, he entered a business with a classic IT function. The technology core was tasked with driving business efficiency and enabling productivity for its employees, offices and factories — all the things you would expect.

"What we weren't asking that organization to do was work from the customer backward and change the role that our products and services can play with them," Campisi said. Data and analytics play a critical part in how products can deliver more value to customers.

Campisi came from GE Digital where he served as chief operating officer, responsible for back-end operations like cybersecurity and cloud. Focused on using software and analytics to direct outcomes and drive value, he was part of the effort to transform GE into a technology company, a far cry from its industrial roots.

UTC ushered in the CDO model because it is unfair to expect an organization that has specialized in one way of working to suddenly contribute to the bottom line, according to Campisi.

The CIO can remain responsible for the backend, allowing the CDO to make disruptive changes throughout the organization, keeping a product-focus in mind.

Taking an IT organization digital requires progress measurements and Campisi sees them in five proxies:

-

"Is our strategy aligned?" UTC has to determine how to measure results and progress, ensuring the alignment of digital and business strategy.

-

Talent. The physicality of UTC's products is a huge draw for talent, but the company has to position itself to lead and transform its workforce to adopt digital solutions.

-

Building new offerings. UTC wants to productize data and analytics, manifesting it in such a way to grow the company and relationships with customers.

-

Digitizing core processes. Introducing digital technologies to core offerings, UTC is working to improve the flywheel of the speed of the company and key performance indicators.

-

Solidifying the foundation. UTC has to execute the basic "blocking and tackling" of cybersecurity, maintain a network that can support the volume of digital and integrate the cloud, among other things.

Highlighting the wins — and lessons learned

Looking at in-factory performance, the supply chain is "super stretched" and anything technology can do to streamline offerings will have an impact, Campisi said. In the aerospace industry in particular, there are 30,000 commercial aircraft in the world and its expected to grow 60% in the next 15 years.

When industrial giants work to go digital, "there has been an element of pushing digital for digital sake," Miller said. But a sensor in an elevator that can measure vibrations or noise could send information back to a support engineer, flagging if someone needs to drop by for unscheduled maintenance.

The data and connection delivers value, but is not outright changing the world on its own, Miller said.

Using design thinking, data and analytics to address some pain points can alleviate some of the burden for people "beholden to process," Campisi said. And with successful implementation, UTC has seen a "significant amount of cash flow improvement because of inventory levels [starting to] coming down, as an example."

Aviation can also benefit from increasing its connected products and injecting data and analytics to boost performance.

"If you can help an airline improve their turn time by like a minute, literally a minute, on every sort of route on any given day, it's like giving them a whole new aircraft in their fleet," Campisi said.

UTC can increase the capacity of an airline just by understanding predictive maintenance instead of waiting for inevitable unplanned downtime.

The company is starting to have success understanding and predicting things much faster, Campisi said. The challenge is changing processes to enable analytics to lead outcomes UTC identifies.

Turning to digital is not without its pitfalls. However, UTC's bets drive business efficiency have a higher success rate, Campisi said. "They're more clear, they're more measurable, you kinda know what you need to know and what you need to do."

But bets that rely on keeping the end-customer happy can prove more challenging to execute.

At vacation resorts, Otis has a significant number of elevators and service contracts on campus. The team was building an app for those responsible for elevators on a campus that would give them visibility into operations.

But UTC's thesis was wrong and the end-customer didn't like it, Campisi said. But because the team only spent six weeks constructing it, it was not a huge loss.

"We're now getting smarter about how do you engage the customer sooner," Campisi said. "How do you take this sort of minimally viable approach that says, lets just show them 5% of what we think we can do to get their feedback and keep rolling forward."

The physical appetite for technology

The workforce has readily adopted digital technology, making the appetite for more streamlined offerings pervasive. The challenge becomes weaving those technologies into an industrial setting.

If you look at a Pratt & Whitney engineer, who works for a business specializing in the design, manufacture and service of aircraft engines, they understand the physics behind how an engine forms, Campisi said. Those engineers physics-based models give them a sense of how the engine is performing.

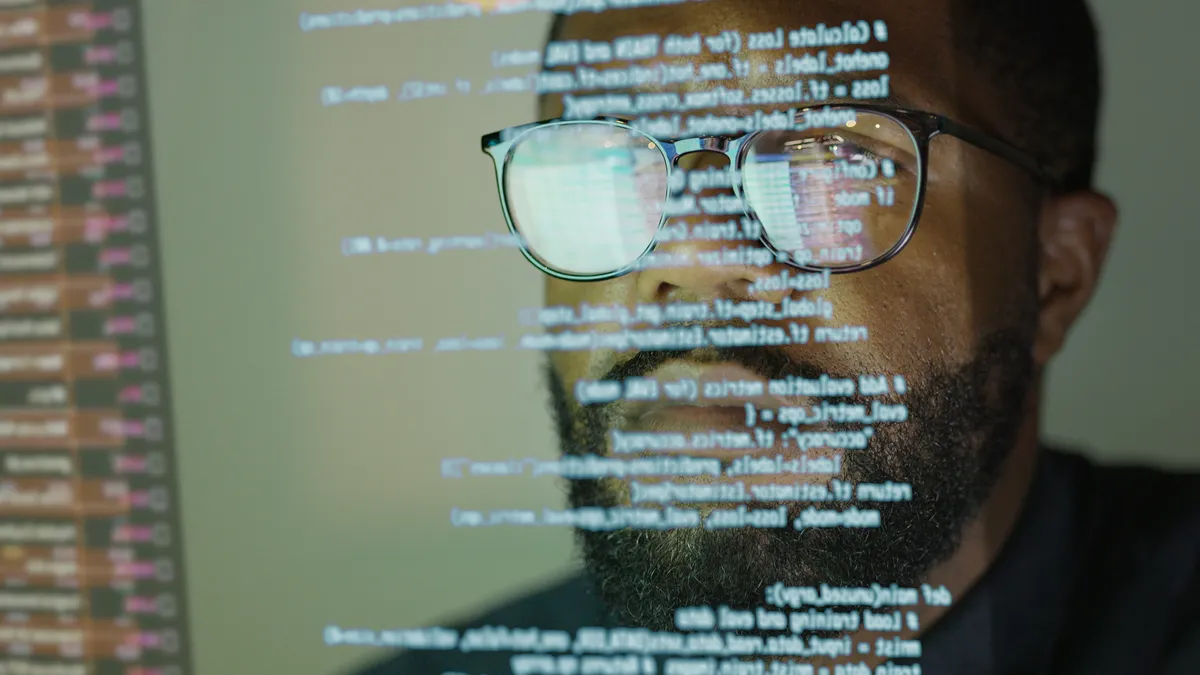

UTC is working on how to integrate machine learning and artificial intelligence to allow people who don't have the domain expertise to come in and analyze the data, Campisi said. Their outside view could identify potential insights contrary or in concert with what the physics-based models say.

"At the end of the day, if we can produce an insight that helps somebody identify an issue before it's happening or earlier in the process, it's got a tremendous value to it," he said. But in order for that insight to drive value, UTC has to convince people to do things like unplanned maintenance on engines.

One of the clear challenges in the industrial worlds is evolving engineers who thrive in the physical world to become more digital, Miller said. "The Silicon Valley stuff makes for great headlines," but purely laying those technologies onto a physical offering will yield little impact.

Engineers need to come along for the ride and businesses need to embrace their expertise, Miller said. Understanding a predictive maintenance schedule, a digital offering will light up red when something appears wrong. But a machinist, with decades of experience, can listen to a machine, touch it and know nothing is wrong.

The true challenge with digital technologies in industrial settings is weaving those two worlds together, Miller said.